Stone Crusher

Localtion:Our Product>VU aggregate optimization system

VU aggregate optimization system

Cheap and easy to get tail, waste, construction waste, stone chips, guamishi and so on

Chat online

Leave message

The VU dry sand making system adopts a highly intensive tower-style fully enclosed layout, which integrates sand making, particle shape optimization, stone powder control, gradation adjustment, moisture content control, and environmental protection treatment. It not only significantly improves production efficiency, but also realizes the mechanism The improvement of various indicators such as sand grain type, gradation, and powder content makes the performance of machine-made sand comparable to natural sand, creating new opportunities and values for the development of sand, cement, and concrete industry chains.

Scope of application: supporting sand making in mixing plants, dry-mixed mortar, cement product factories, aggregate mines, large-scale construction projects, etc.

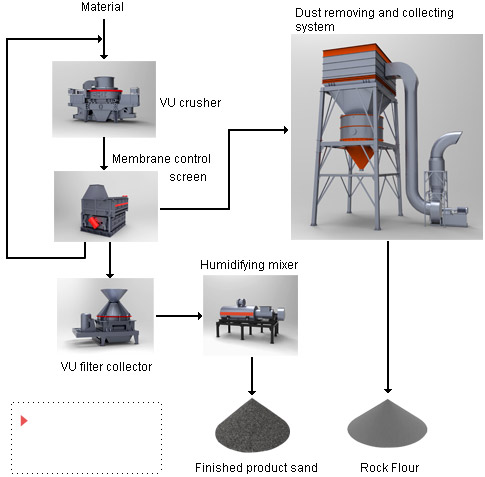

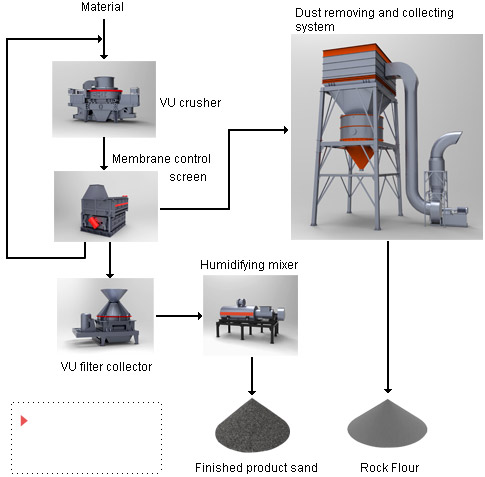

Working principle: The raw material is sent to the VU impact crusher through lifting, and then enters the mold-controlled sieve after being ground by high-frequency stone-beating stone. After sorting, according to the sieving results, the material on the sieve returns to the VU impact crusher for processing, and the material on the sieve enters the VU grain refiner for processing. Material reshaping, while the entire mold control sieve controls the powder content in the material through the wind selection of the dust collector, and finally the VU particle refiner discharges the material and mixes the material evenly through the humidifying mixer. After being processed by the VU aggregate optimization system, the finished sand with reasonable gradation, round grain shape and controllable powder content is produced, as well as dry and clean high value-added stone powder that can be recycled uniformly.

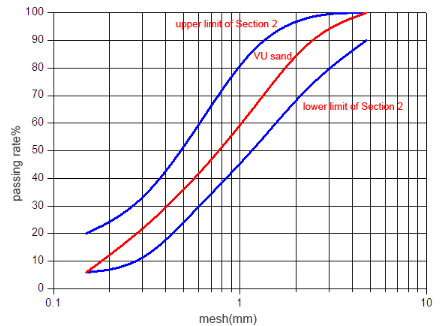

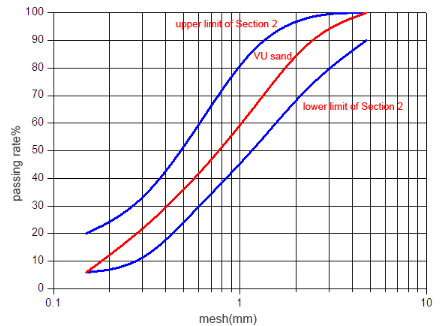

It is generally accepted that 2-area medium size sand is the better choice for making concrete because of its good shape and appropriate size. To the contrary, due to the large content of coarse sand and sand powder and small quantity of fine sand, the normal machine-making sand can not meet the standard of the 2-area medium size sand. When using it to make the concrete, it will lead to large quantity of cement paste and poor peaceability.

Liming VU gravel aggregate system can well control the sand gradation curve in grading area 2. When compounding concrete with the same cement, the production mechanism of Liming VU gravel aggregate system could help you with a higher strength which greatly meet the sand requirements on various kinds of concrete and dry-mixed mortar.

VU sand aggregate gradation graph

VU sand aggregate gradation graph

Recommended news

Recommended Project