iron ore processing plant design solutions mineral

Designing an iron ore processing plant requires a deep understanding of the mineral's characteristics and how they can be processed to produce high-quality iron ore products. There are several factors that need to be considered when designing an iron ore processing plant, including the type of ore being processed, the desired end product specifications, and the available technology and equipment.

Here are some possible solutions for iron ore processing plant design:

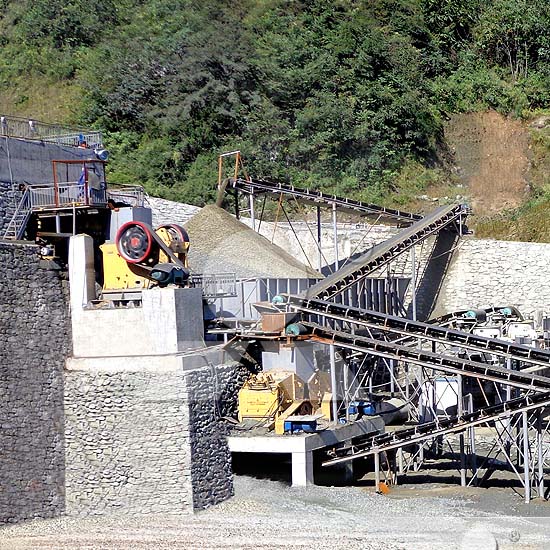

Crushing and Screening: The first step in processing iron ore is to crush and screen the ore to remove impurities and prepare it for further processing. The crushing process can be done in several stages, depending on the size of the ore and the desired end product. Typically, the ore is crushed in a primary crusher, followed by secondary and tertiary crushers to reduce the ore to the desired size.

Grinding and Classification: Once the ore has been crushed, it needs to be ground to a fine powder to enable separation of the iron-containing minerals from the gangue minerals. Grinding is usually done using a ball mill or similar equipment, and the resulting powder is then classified based on size to ensure that the particles are of the desired size for further processing.

Magnetic Separation: Magnetic separation is a common method used to separate iron-bearing minerals from non-magnetic minerals. This process involves passing the crushed and ground ore through a magnetic field, which causes the iron particles to be attracted to the magnet and separated from the non-magnetic particles.

Flotation: Flotation is another common method used to separate minerals from each other based on their surface properties. In this process, the crushed and ground ore is mixed with water and a flotation agent, and then agitated to create bubbles. The bubbles attach to the desired mineral particles, causing them to rise to the surface where they can be collected and separated from the rest of the ore.

Dewatering: After the desired minerals have been separated from the ore, the remaining slurry needs to be dewatered to remove excess water. This can be done using a variety of methods, including thickening, filtration, and drying.

Product Handling: Once the iron ore has been processed, it needs to be transported and stored. This requires careful consideration of the product's characteristics, such as moisture content, particle size, and abrasiveness, as well as the available transportation and storage facilities.

In summary, designing an iron ore processing plant requires a comprehensive understanding of the mineral's characteristics and the available technology and equipment. The solutions outlined above provide a framework for designing a processing plant that can efficiently and effectively produce high-quality iron ore products.

Recommended news