difference of vertical raw mill and ball mill-ball mill vs vertical roller mill

Both ball mills and vertical roller mills (VRMs) are used for grinding materials in the cement industry, but they have different operating principles, design features, and advantages. Here’s a brief overview of the difference between a vertical raw mill and a ball mill:Vertical raw mill:

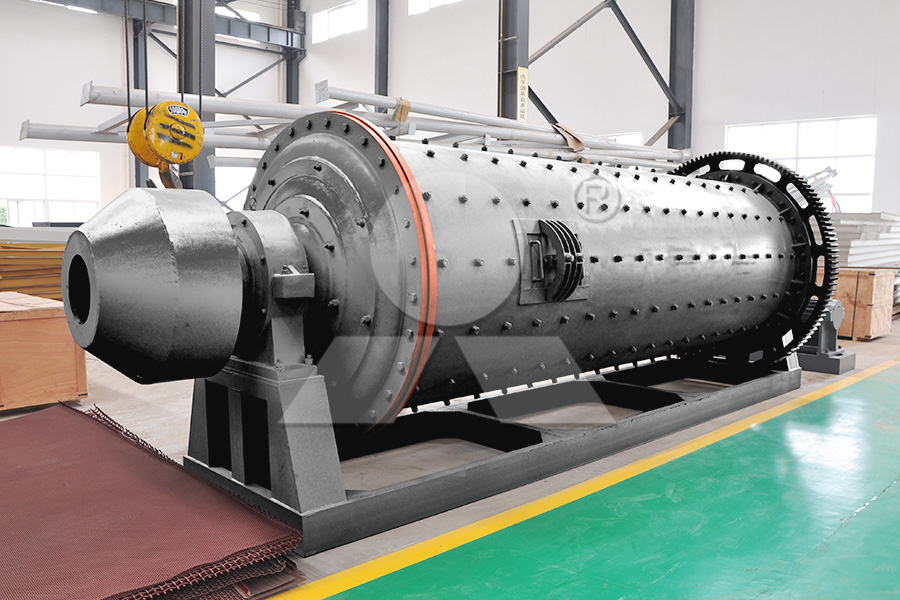

The main differences between a vertical raw mill and a ball mill are:1.Grinding mechanism: The grinding mechanism of a vertical raw mill is between the grinding table and rollers, while the grinding mechanism of a ball mill is between the rotating cylinder and steel balls.2.Energy consumption: The vertical raw mill consumes less energy than a ball mill.3.Floor space requirement: The vertical raw mill has a smaller footprint compared to a ball mill, which makes it more suitable for smaller installations.4.Maintenance: The vertical raw mill is easier to maintain than a ball mill, as it has fewer moving parts and a simpler mechanism.

In summary, while both vertical raw mills and ball mills are used for grinding materials in the cement industry, they have different operating principles, design features, and advantages. The choice between the two types of mills depends on various factors, such as the required particle size, energy consumption, and floor space availability.