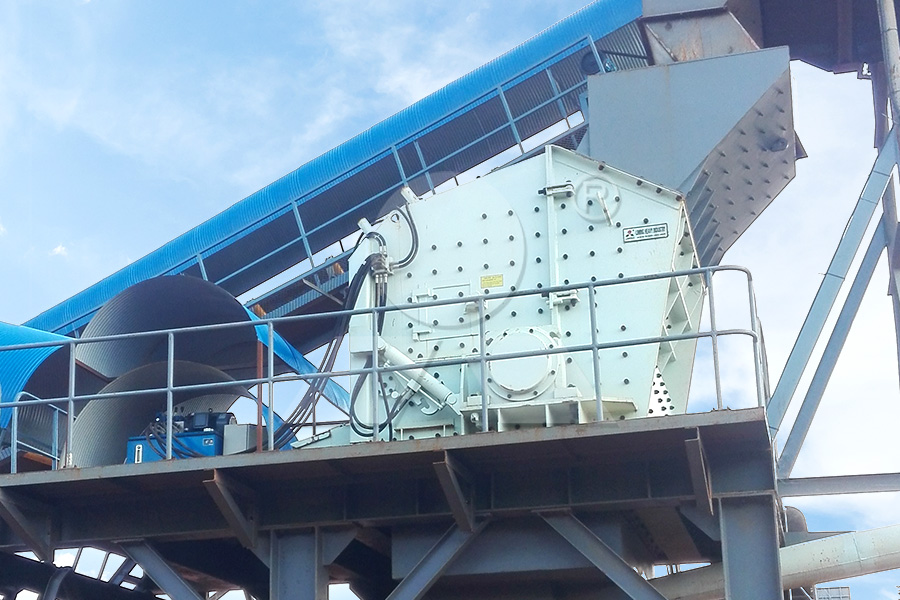

Enhancing Industrial Processes: Unleashing the Impressive Features of Impact Crushers

Impact crushers have become invaluable assets in various industrial processes, offering exceptional performance and efficiency. These powerful machines are designed to crush and shape a wide range of materials, making them indispensable in industries such as mining, construction, and recycling. This article explores the impressive features of impact crushers and their impact on enhancing industrial processes.

Versatile Crushing Capabilities

One of the standout features of impact crushers is their versatile crushing capabilities. They can handle a variety of materials, including hard and abrasive ones such as limestone, granite, and concrete. This versatility allows for efficient processing of different feed materials, making them suitable for a wide range of industrial applications.

Precise Particle Size Control

Impact crushers excel in providing precise control over the particle size distribution of the crushed material. With adjustable settings and specialized crushing chambers, they can produce a wide range of particle sizes, ensuring the desired product specifications. This control is particularly important in industries that require specific particle sizes, such as aggregate production for road construction or recycling applications.

High Production Efficiency

Impact crushers are known for their high production efficiency, allowing for large quantities of material to be processed in a short period. Their unique crushing mechanism, typically involving rapid rotation and high-speed impact, enables efficient material reduction and high throughput. This translates to increased productivity and cost-effectiveness in industrial processes.

Minimal Downtime and Maintenance

Manufacturers have designed impact crushers with ease of maintenance in mind. They incorporate features such as easily accessible wear parts, hydraulic adjustment systems, and robust construction to minimize downtime and maintenance requirements. This ensures that industrial processes can run smoothly and uninterrupted for extended periods, maximizing productivity.

Environmental Considerations

Impact crushers also contribute to environmental sustainability. By efficiently reducing material size and recycling waste, they support resource conservation and minimize waste sent to landfills. Additionally, the use of impact crushers in recycling applications helps reduce the demand for virgin materials, promoting a more sustainable approach to industrial processes.

The impressive features of impact crushers make them essential tools for enhancing industrial processes across various sectors. Their versatility, precise particle size control, high production efficiency, and minimal downtime contribute to improved productivity and cost-effectiveness. Moreover, their environmental considerations align with the growing focus on sustainable practices. As industrial processes evolve, impact crushers will continue to play a pivotal role in shaping the future of industries such as mining, construction, and recycling.