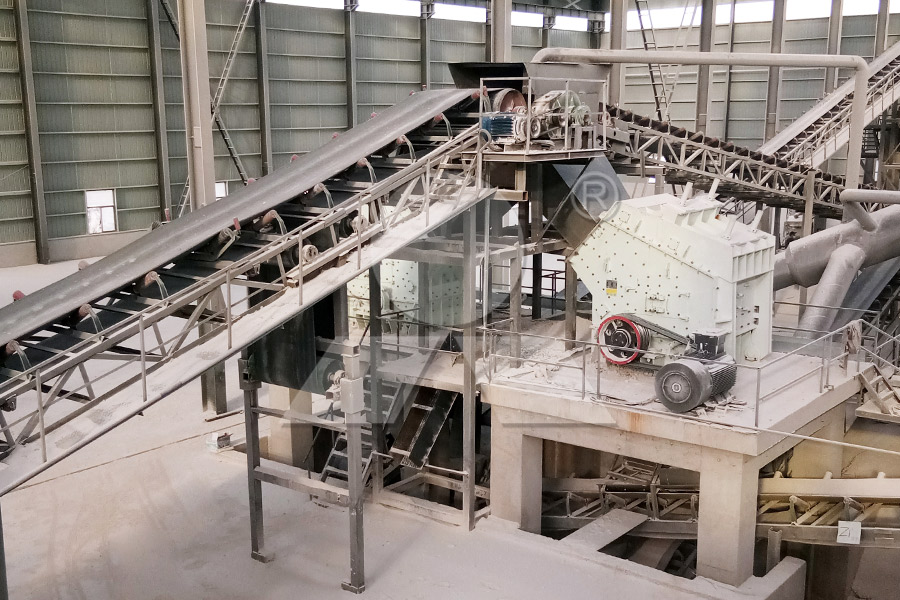

Impact Crusher: Transforming Cement Production with Efficient Crushing

In the cement production process, efficient and high-quality crushing equipment plays a vital role. Impact crushers have emerged as a game-changer in the field of cement production, offering enhanced crushing capabilities and optimizing the overall efficiency. In this article, we will explore how impact crushers are transforming cement production, delivering reliable and efficient crushing for the industry.

1.Enhanced Crushing Performance:

Impact crushers in cement production excel in crushing performance, delivering consistent and high-quality end products. These crushers utilize the impact principle to crush the raw materials, providing efficient and uniform reduction of the material size. The robust rotor design and high-speed rotation ensure effective impact force, enabling the crusher to handle even the toughest materials.

2.Versatility in Material Processing:

Impact crushers offer versatility in material processing for cement production. They can effectively crush various materials, including limestone, clay, shale, and other raw materials used in cement production. The adaptability of impact crushers allows for efficient crushing of different material sizes and hardness levels, catering to diverse cement production needs.

3.Efficient Size Reduction:

Impact crushers are designed to efficiently reduce the size of raw materials, enabling easier and more efficient processing in cement production. By breaking down larger materials into smaller, more manageable sizes, impact crushers optimize the subsequent steps in the production process. This efficient size reduction improves overall productivity and reduces energy consumption.

4.Consistent Product Quality:

Impact crushers in cement production ensure consistent product quality by producing well-graded and uniform-sized materials. The controlled impact force and adjustment options allow operators to achieve the desired product specifications. This consistency in product quality enhances the performance of downstream processes, such as grinding and blending, resulting in high-quality cement production.

5.Versatile Application in Cement Production:

Impact crushers find versatile application in various stages of cement production. They can be used as primary crushers to break down large-sized raw materials, as secondary crushers for further size reduction, or even as tertiary crushers for fine crushing. This versatility allows impact crushers to be effectively utilized throughout the cement production process.

6.Safety and Maintenance:

Impact crushers prioritize safety and ease of maintenance in cement production. They are equipped with safety features to ensure operator safety during operation. Additionally, impact crushers are designed for easy access to critical components, facilitating quick and efficient maintenance. This minimizes downtime and maximizes the availability of the crusher in cement production operations.

Impact crushers have revolutionized cement production by offering efficient and high-quality crushing capabilities. With their enhanced crushing performance, versatility in material processing, and efficient size reduction, impact crushers optimize the overall cement production process. The consistent product quality, versatile application, and focus on safety and maintenance make impact crushers a valuable asset in cement production. As the demand for efficient and reliable crushing solutions continues to grow, impact crushers stand as a reliable and efficient tool in cement production, transforming the industry with their powerful impact force and optimized crushing capabilities.