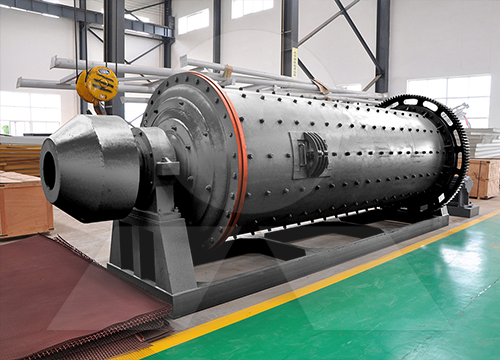

Factors Influencing Ball Mill Performance

Ball mills are widely used in various industries for grinding materials into fine powder. To maximize their efficiency and productivity, it is crucial to understand the factors that affect ball mill performance. In this article, we will explore the key factors that influence ball mill efficiency, allowing operators to optimize their grinding processes and achieve higher productivity.

1.Mill Design and Geometry:

The design and geometry of the ball mill directly impact its efficiency. Factors such as the mill diameter, length, and internal configuration play a crucial role in determining the grinding efficiency. The correct proportion of mill length to diameter, along with appropriate lifter and liner designs, ensures efficient grinding and proper cascading of grinding media, optimizing the energy transfer within the mill.

2.Grinding Media Characteristics:

The characteristics of the grinding media significantly affect ball mill efficiency. Factors such as the size, shape, and composition of the grinding media influence the grinding kinetics and energy consumption. Using grinding media with the right combination of size and material properties ensures effective grinding, reducing energy waste and improving grinding efficiency.

3.Feed Size and Distribution:

The feed size and distribution of the material being ground are critical factors in ball mill efficiency. A fine and evenly distributed feed size allows for efficient grinding and prevents excessive grinding of oversized particles. Proper classification and control of feed size distribution using techniques such as pre-screening or cyclone separators can optimize grinding efficiency and maximize throughput.

ball mill4.Mill Speed and Load:

The rotational speed and loading of the ball mill affect its efficiency. Operating the mill at the optimal speed for the given material and grinding conditions is essential to achieve maximum grinding efficiency. Additionally, maintaining the correct mill load, ensuring the mill is neither under-loaded nor overloaded, is crucial for efficient grinding and minimizing energy consumption.

5.Grinding Aid Addition:

The use of grinding aids can enhance the grinding efficiency of ball mills. Grinding aids improve particle dispersion and reduce agglomeration, resulting in a finer and more efficient grinding process. Proper selection and dosage of grinding aids tailored to specific materials and operating conditions can significantly improve ball mill efficiency.

6.Moisture Content:

The moisture content of the material being ground affects ball mill efficiency. High moisture content can result in poor flowability and increased energy consumption due to the need for additional drying. Proper control of material moisture, either through pre-drying or adjusting the mill parameters, ensures optimal grinding efficiency and prevents energy losses.

7.Ball Mill Circuit Control:

Effective control of the ball mill circuit is crucial for maximizing efficiency. Implementing advanced control systems, such as model predictive control (MPC) or fuzzy logic control, allows for real-time monitoring and adjustment of various operating parameters. These control systems optimize the grinding process, maintain stable mill operation, and ensure consistent product quality, enhancing overall ball mill efficiency.