What is the name of the machine that makes all kinds of powder?

The machine for making all kinds of powder, that is, the industrial powder making equipment capable of grinding various ores into 80-1000 mesh fineness, suitable for nearly 300 kinds of limestone, dolomite, kaolin, barite, calcite, talc, etc. Stone, so what is the name of this machine for making all kinds of powder?

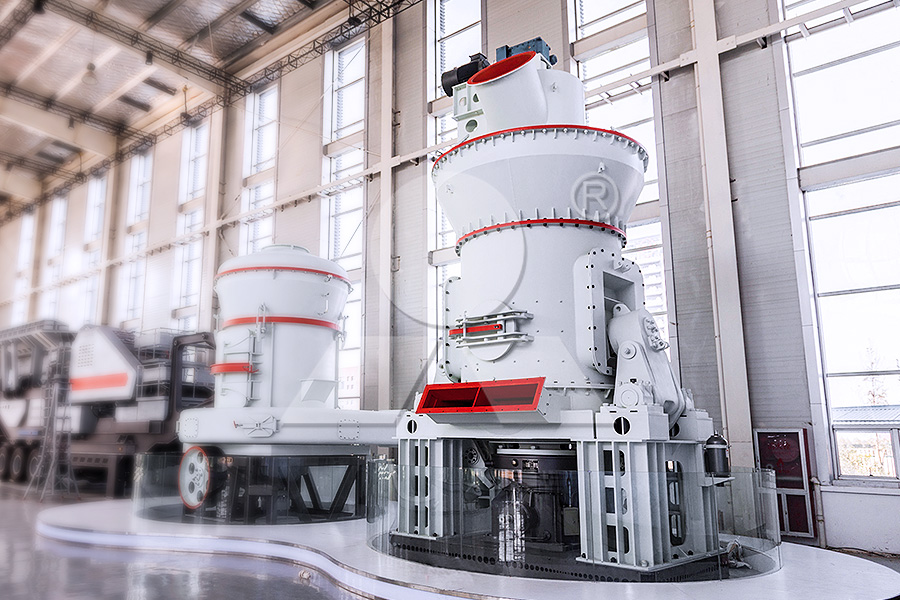

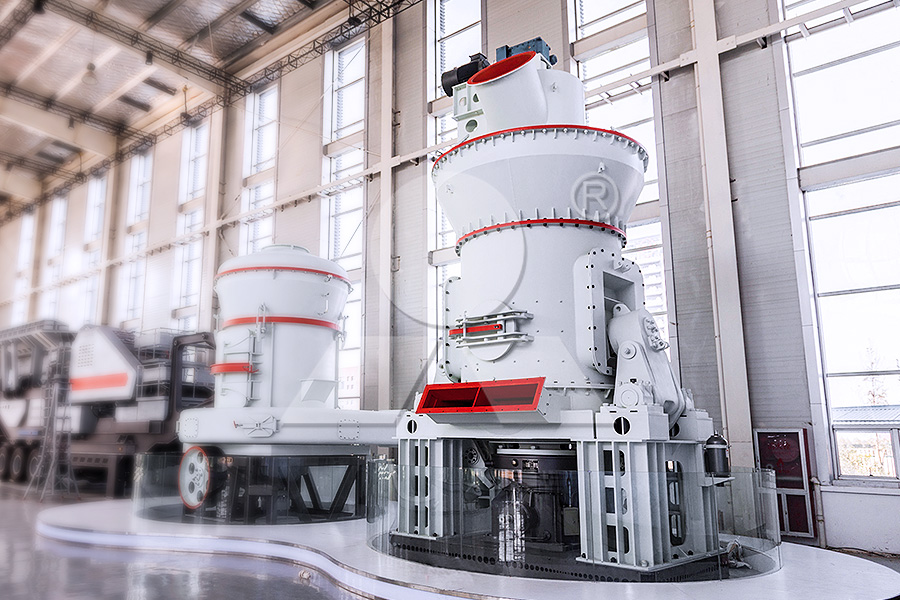

The machine for making all kinds of powder is called mill, also known as stone mill, which is widely used in construction, chemical, rubber, paper, daily industrial supplies and other industries, and there are many types of equipment, commonly used are Raymond mill, Vertical roller mills, high-pressure suspension roller mills, etc., each series is subdivided into multiple models, each of which has its own characteristics, it is difficult to say which one is better, because the needs of each user are different, it should be combined with the actual to choose.

The daily output of Raymond Mill is 8-78 tons, the processing particle size is ≤25mm, and it is crushed into powder of 0.8-0.045mm; the transmission device of the main engine adopts a sealed gear box and a pulley, with stable transmission, reliable operation, small footprint, and intelligent operation system; coupled with the new pulse dust removal equipment, the dust removal is thorough, the pollution is reduced, the material is uniformly discharged, the sorting accuracy is high, and the quality of the finished fine powder is high.

LM vertical roller mill is an energy-saving mill equipment that combines mature vertical mill technology, successful experience abroad and our company's technological innovation and upgrade. Integrating crushing, drying, grinding, grading and conveying, the layout is compact and occupies a small area; it mainly focuses on the three major fields of non-metallic ore, coal powder and slag, and has mature technology, which can be applied to the grinding of raw material and clinker , It can also be used as a pre-grinding equipment to greatly increase the production and energy saving of subsequent mills.

High-pressure suspension roller mills are widely used in metallurgy, building materials, chemicals, mines, highways, water conservancy and hydropower and other industries. They are suitable for processing various non-flammable and explosive materials with Mohs hardness below 9.3 and humidity below 6%. 0.613mm—0.033mm, special devices can also be added to grind 30~80 mesh coarse powder.

Recommended news

- Barite Limestone Mining Raymond Mill Machine

- advantage of vertical roller mill for cement grinding

- quarry plant rock raymond mill for building materials

- MTW European version of the mill than Raymond mill in what is better

- Demystifying the Operational Principles of Raymond Mill

- Mills that meet environmental protection standards can be put into production normally