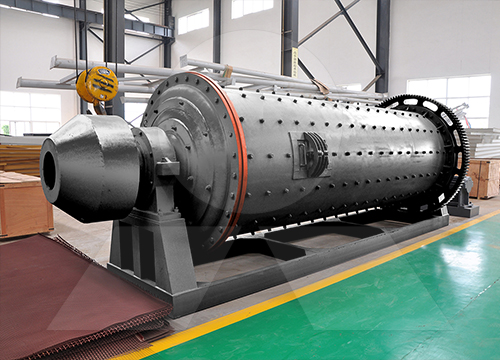

Ball mill introduction

Ball mill, also known as grinding mill, is a commonly used equipment for grinding or milling various ores and other grindable materials in dry or wet conditions. It has strong adaptability, can achieve continuous production, and has a high crushing ratio. Ball mills come in small, medium, and large sizes. In this article, we will discuss the process flow and analysis of the advantages and disadvantages of a small-sized ball mill.

The price range of small ball mills on the market is quite large, ranging from tens of thousands to four or five hundred thousand yuan. The price difference is due to different production capacity requirements and the selection of different models. Additionally, each manufacturer has different material selection, processes, and pricing standards, leading to significant variations in quotations that may not always be accurate.

There are currently over 30 models of ball mills available, with hourly production capacities ranging from 0.65 to 615 tons. They allow feed sizes of less than or equal to 25mm and produce particles with sizes between 0.074 and 0.89mm. Customization is also available based on specific needs.

Which model should be chosen? It depends on specific requirements. If the construction site is small, requires lightweight equipment, and has a limited budget, determining the appropriate model is not as simple as a few sentences. It is important to consider the characteristics of the processed materials (including their composition), the upstream and downstream products used in conjunction with the ball mill, and the subsequent separation operations after grinding. These factors are crucial in selecting the suitable model.

Recommended news