silver stone crusher sand making stone quarry

In a quarry setting, a silver stone crusher typically refers to a stone crusher machine or equipment used for crushing silver-containing rocks or ores into smaller sizes. The crushed silver stones can then be used in various applications, including sand production for construction and building projects.

When it comes to sand making in a quarry, the process usually involves the following steps:

Primary Crushing: The silver-containing rocks or ores are initially crushed by a primary crusher, such as a jaw crusher or gyratory crusher, to reduce their size and prepare them for further processing.

Secondary and Tertiary Crushing: If necessary, the crushed silver stones may undergo secondary and tertiary crushing stages using cone crushers or impact crushers. This helps to further reduce the size of the material and produce the desired particle size for sand production.

Screening: The crushed silver stone material is then screened using vibrating screens. This process separates the stones into different sizes or grades, ensuring that only the desired sizes are used for sand production.

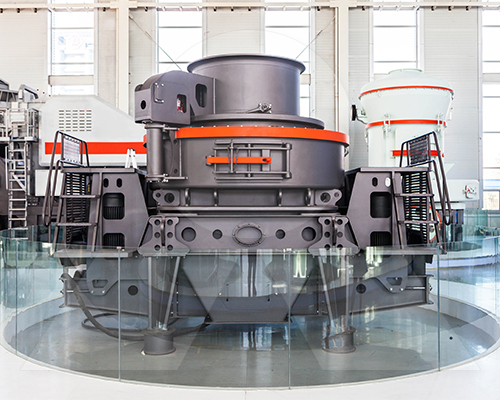

Sand Making: After screening, the appropriately sized silver stones are sent to a sand-making machine, such as a vertical shaft impact crusher or sand making machine. These machines use high-speed rotating impellers to crush and shape the silver stones into sand particles.

Washing and Grading: In some cases, sand produced from a silver stone crusher in a quarry may undergo additional processes, such as washing and grading, to remove impurities and achieve the desired quality and consistency.

It's worth noting that the specific equipment and processes used in a quarry for sand production can vary depending on the location, the type of silver stone being processed, and the desired specifications of the final sand product.

Recommended news