Marble powder from stone processing industry

Marble powder is a fine powder residue generated during the cutting, grinding, and polishing of marble stones in the stone processing industry. It is produced as a byproduct when marble is processed into various shapes, slabs, tiles, and other products. Instead of being discarded as waste, marble powder can be utilized in various applications due to its properties.

Here are some common uses of marble powder from the stone processing industry:

Marble powder can be used as a partial replacement for cement or as a fine aggregate in concrete and mortar. It improves the workability, strength, and durability of the concrete while reducing the environmental impact of cement production.

Marble powder can be incorporated into the production of tiles, terrazzo flooring, and decorative elements to enhance their aesthetic appeal. It can be mixed with resins or binders to create marble-like patterns or as a filler material.

Marble powder can be used as a pigment or filler in the manufacturing of paints, coatings, and pigmented plasters. It provides a unique texture, brightness, and sheen to the surface.

Due to its fine particle size, marble powder can be used as a filler material in various applications such as rubber, plastics, adhesives, and sealants. It improves the mechanical properties and reduces costs.

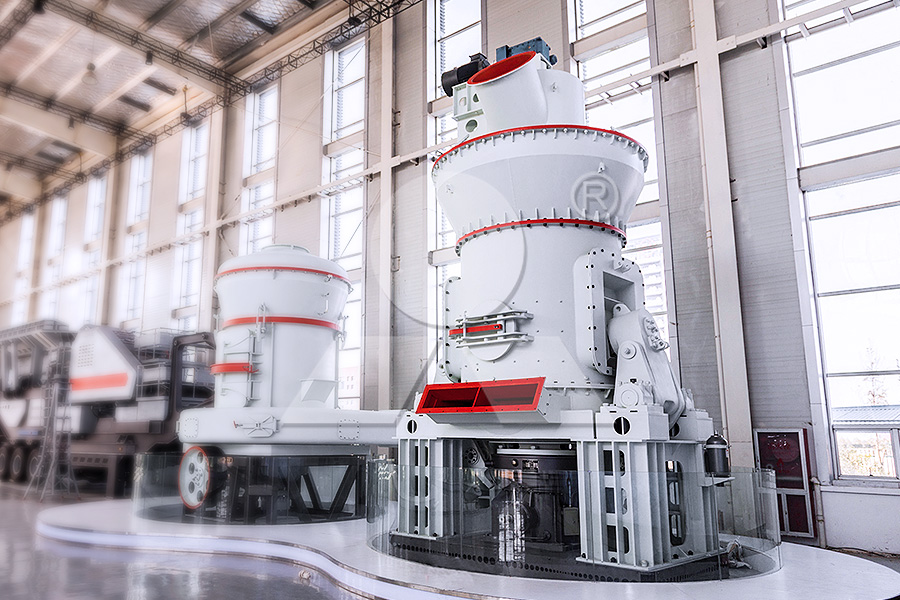

If you want to get marble powder, you can use our vertical mill. The large material is crushed by the crusher to the feed fineness (15mm-50mm) that can enter the mill. If it is marble scrap, it meets the feed particle size requirements. , then broken. The small pieces of material that meet the grinding conditions enter the grinding chamber of the mill evenly and quantitatively through the conveying and feeding system, and are ground into powder in the grinding chamber.

Recommended news