Tibet Lhasa River pebble sand EPC project

The client, Lhasa City Investment, is a state-owned enterprise wholly owned by the State-owned Assets Supervision and Administration Commission. It has participated in more than half of the local municipal engineering, road and bridge construction, real estate development and other projects, and has strong financial resources and rich experience. This project is located in Dazi Industrial Park, covering an area of 170,000 square meters. It is a new type of stone processing plant integrating environmental protection, energy saving and high production. Most of the stones produced are used by its commercial and mixing stations.

Processing material: river pebbles

Production capacity: 500T/H

Discharge granularity: 0-5mm, 5-13mm, 13-25mm, 25-31.5mm

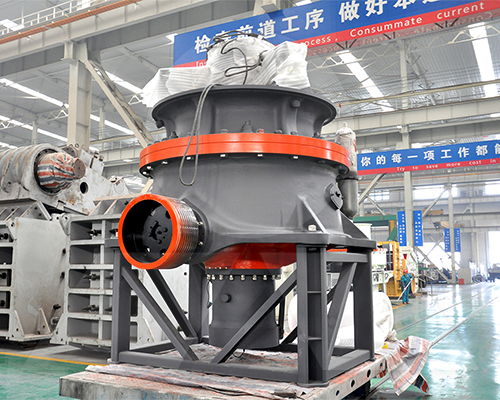

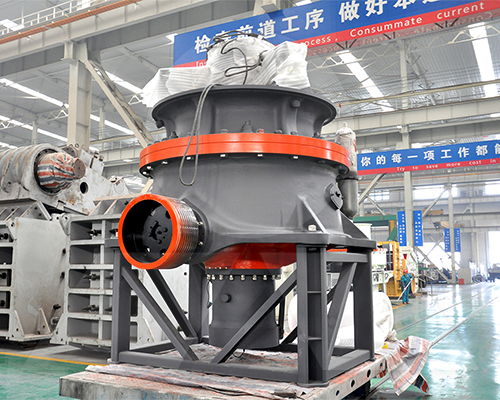

The raw material enters the C6X145 jaw crusher through the F5X1860 bar vibrating feeder for primary crushing, in which the ≤200mm material passes through the feeding bar bar sieve, and is directly transported to the S5X2760-3 vibrating screen for screening and washing treatment, and the finished sand in the raw material is screened After washing, it directly enters the finished product warehouse of far sand. Among them, the ≥200mm material is crushed by the jaw crusher, and enters the block rock buffer bin together with the 5~200mm material, and the material in the block rock buffer bin is sent to the HST315S2 coarse crushing single-cylinder cone crusher through the belt conveyor for secondary crushing, and then passes through the coarse crushing cone crushing process. The final material enters the 2YK3X3075 vibrating screen for screening treatment, returns the material ≥ 40mm to the medium stone buffer bin (when the pressure of the middle stone buffer bin is high, it can be returned to the block rock buffer bin), and then enters the HST315H2 fine crushing cone crusher and S5X2760-2 Vibrating screen screening forms a closed loop. ≤40mm semi-finished product mixture enters the semi-finished buffer silo, is shaped and sanded by VSI6X1263 vertical impact breaker, and then enters S5X2760-3 vibrating screen for screening and classification, and the finished material is finally transported to each finished product silo for storage. In addition, the finished materials are washed with water to ensure the quality of the finished materials. At the same time, the generated sludge water passes through the fine sand recovery device and enters the sewage treatment system for recycling.

Related project